Discover the Creativity of In-Mold Decorations in Production

Discover the Creativity of In-Mold Decorations in Production

Blog Article

Grasping In-Mold Decorations: Approaches, Patterns, and Best Practices for Optimum Results

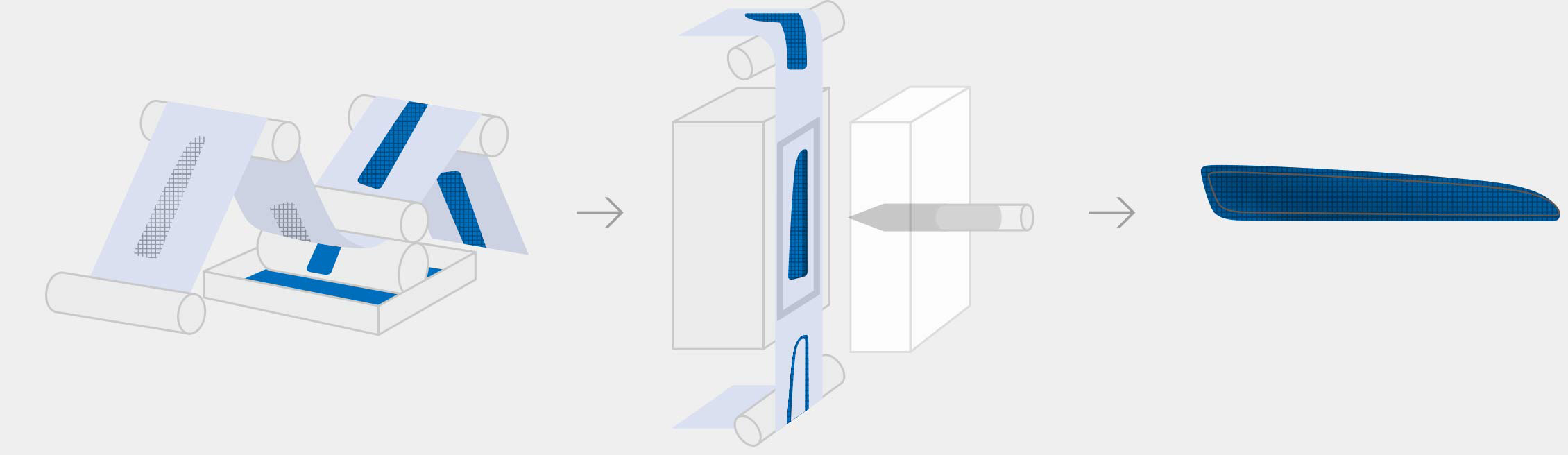

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of product layout and production. As sectors constantly look for innovative methods to boost visual allure and functionality, understanding the intricacies of in-mold designs has actually arised as an important skill set. From picking the best products to incorporating sophisticated design patterns, the trip towards accomplishing ideal results in this domain is diverse. By delving right into the techniques, patterns, and ideal practices that underpin effective in-mold design procedures, businesses can unlock a world of opportunities that not just elevate the aesthetic allure of their products however additionally streamline manufacturing performance and bolster consumer interaction.

Material Selection

Material selection is a vital element of grasping in-mold designs, as it straight affects the high quality and toughness of the end product. When selecting materials for in-mold designs, it is important to consider factors such as compatibility with the molding process, the wanted aesthetic end result, and the ecological problems the item will certainly encounter. Thermoplastic products like polycarbonate, polypropylene, and abdominal muscle are typically made use of for in-mold decors due to their adaptability and ability to achieve detailed styles. These materials offer excellent moldability, allowing manufacturers to produce intricate forms and patterns with accuracy.

In addition, products with high warm resistance are chosen for in-mold decorations, specifically for products that will certainly be subjected to elevated temperature levels throughout their lifecycle. By carefully choosing the suitable material for in-mold designs, makers can improve the total high quality and toughness of their products, satisfying the assumptions of both clients and end-users - In-Mold Decorations.

Design Technology

An important consider progressing the area of in-mold designs is the continuous exploration and application of design technology methods. Design innovation plays a critical function in enhancing the aesthetic appeal, functionality, and overall high quality of products produced utilizing in-mold design procedures. By incorporating innovative layout components, makers can distinguish their items out there, draw in consumers, and remain ahead of rivals.

Among the essential aspects of layout technology in in-mold designs is the integration of detailed patterns, appearances, and graphics that were formerly testing to attain with standard design techniques. Advanced innovations such as 3D printing and digital layout tools enable developers to create facility and comprehensive layouts that can be effortlessly transferred onto shaped parts. Additionally, using lively colors, metal finishes, and special results like gloss or matte structures can even more raise the visual appeal of in-mold enhanced items.

Furthermore, design technology extends past aesthetics to include useful enhancements such as ergonomic forms, integrated functions, and personalized elements that provide to specific customer requirements. By welcoming design advancement, manufacturers can unlock new possibilities for customization, item, and creativity differentiation in the competitive landscape of in-mold designs.

Production Effectiveness

Reliable manufacturing procedures are important for equating why not try this out the ingenious styles established in the area of in-mold designs right into high-quality finished products that meet market demands and consumer assumptions. In the world of in-mold designs, manufacturing performance incorporates numerous key facets that add to the general success of the manufacturing process. One vital aspect is the optimization of mold and mildew design and tooling to make sure smooth and specific decor transfer onto the last product. By fine-tuning mold setups and buying premium tooling materials, producers can enhance performance and uniformity in production.

Automation not just accelerates the production process but likewise enhances accuracy and repeatability, leading to an extra top quality and uniform end product. In general, a holistic method to production efficiency is critical in optimizing the possibility of in-mold decor strategies and achieving optimal outcomes in the affordable market landscape.

Quality Assurance Actions

What are the key strategies for making certain rigorous top quality control actions in the world of in-mold decors? Quality assurance procedures are vital in in-mold decor procedures to guarantee the production of high-quality and remarkable finished products. One crucial approach is the execution of extensive evaluation protocols at every phase of the production process. This entails conducting thorough aesthetic assessments, dimensional checks, and color consistency analyses to determine any inconsistencies or defects beforehand.

Making use of sophisticated modern technologies such as computerized assessment systems can additionally improve the quality assurance process by giving trusted and precise information for analysis. These systems can discover blemishes that may be missed by hand-operated inspections, thus boosting general product high quality and uniformity.

Normal training and development programs for employees included in the in-mold decoration process can likewise add to maintaining premium standards. By informing team on best practices, high quality assumptions, and the relevance of focus to information, firms can promote a society of quality consciousness throughout the organization.

Consumer Allure

To enhance the marketability of in-mold decoration products, comprehending and catering to customer preferences play a crucial duty in establishing their allure and useful reference success. Customer appeal in in-mold decorations is influenced by various factors, including design aesthetics, color selections, resilience, and total performance. Consumers are progressively seeking individualized and unique products that reflect their individuality and style. Therefore, offering modification alternatives such as personalized layouts, shade variants, and textural aspects can considerably enhance the appeal of in-mold decor items.

Conclusion

In-mold decorations offer a reliable and versatile means to boost item looks. Grasping YOURURL.com in-mold decorations calls for an all natural approach that considers all elements of the manufacturing procedure to make sure success.

In the realm of production, the art of in-mold decors stands as an essential element of product layout and production. Design technology plays a vital duty in improving the aesthetic allure, performance, and overall top quality of products made utilizing in-mold decor procedures.One of the crucial aspects of layout advancement in in-mold decorations is the assimilation of elaborate patterns, structures, and graphics that were previously testing to accomplish with traditional design methods.Effective production procedures are important for translating the ingenious designs established in the area of in-mold designs right into premium ended up products that fulfill market demands and customer assumptions. Providing modification options such as individualized designs, color variants, and textural elements can substantially boost the appeal of in-mold design items.

Report this page